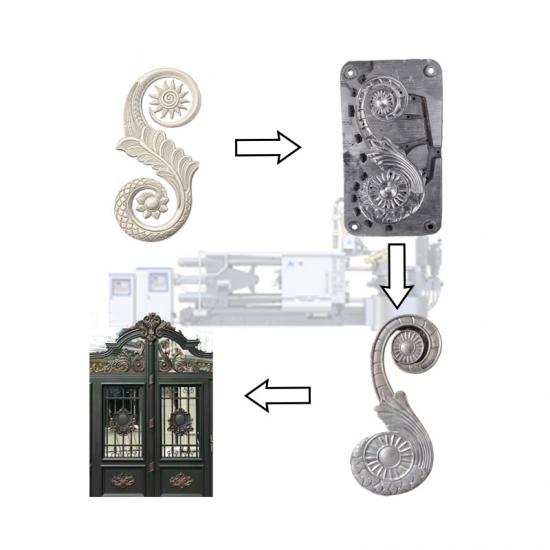

The aluminum alloy cold chamber die casting machine has many advantages, making it one of the commonly

used equipment in aluminum alloy die casting processing. Here are some of the main advantages:

1. High-quality casting surface quality: By controlling the temperature and pressure of aluminum alloy, the cold

chamber die-casting machine can produce castings with smooth surfaces and high precision, reducing or

avoiding defects such as pores and bubbles.

2. Manufacturing high-strength castings: Since the cold chamber die casting machine uses a high-pressure

injection casting process, the density of aluminum alloy castings is higher, so stronger and higher-strength

parts can be manufactured.

3. Good dimensional stability: The cold chamber die casting machine can effectively control the temperature

and pressure during the casting process, making the dimensional stability of the castings better, reducing

problems such as thermal deformation and shrinkage, and improving the processing accuracy and

consistency of parts. .

4. Efficient production: The cold chamber die-casting machine has functions such as rapid injection,

cooling and demoulding. It has high production efficiency and can meet the needs of mass production and

reduce production costs.

5. Energy saving and environmental protection: Compared with traditional hot chamber die casting machines,

cold chamber die casting machines can reduce energy consumption during the production process, reduce

energy costs, and reduce aluminum alloy waste, which meets the requirements of energy conservation and

environmental protection.

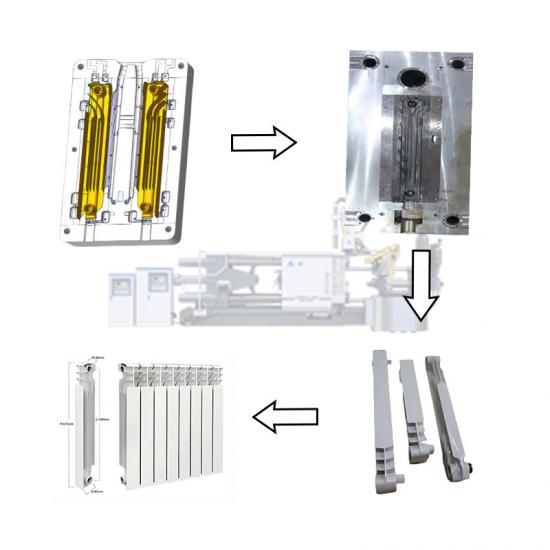

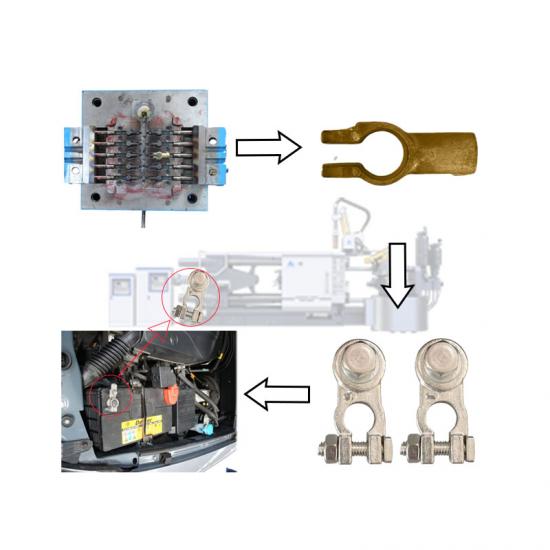

6. Wide range of applications: Cold chamber die casting machines are suitable for various types of aluminum

alloy materials and can be used in the manufacturing of parts in automobiles, aerospace, electronic products

and other fields.

Specification

| LH series of standard parameter table (300 t) | ||

| ITEMS | Unit | Specification |

| Clamping Force | KN | 3000 |

| Opening stroke | mm | 460 |

| Die thickness(Min--Max) | mm | 250~700 |

| Space between tie bars | mm | 570*570 |

| Ejector stroke | mm | 100 |

| Ejector force | KN | 150 |

| Injection position(0 as center) | mm | 0,-160 |

| Injection force(intensification) | KN | 350 |

| Injection stroke | mm | 410 |

| Plunger diameter | mm | ¢50 --¢70 |

| lnjection weight(aluminum) | Kg | 3.2 |

| Casting pressure (intensification) | MPa | 143/99/73 |

| Max. casting area(40Mpa) | CM2 | 720 |

| Injection plunger penetration | mm | 140 |

| Diameter of pressure chamber flange | mm | 110 |

| Height of pressure chamber flange | mm | 10 |

| Max.working pressure | MPa | 14 |

| Motor power | Kw | 15 |

| Dimensions (L*W*H) | m | 6.6*1.85*2.8 |

| Machine lifting reference weight | T | 12.5 |

| Oil tank capacity | L | 700 |

will not be changed without notice)

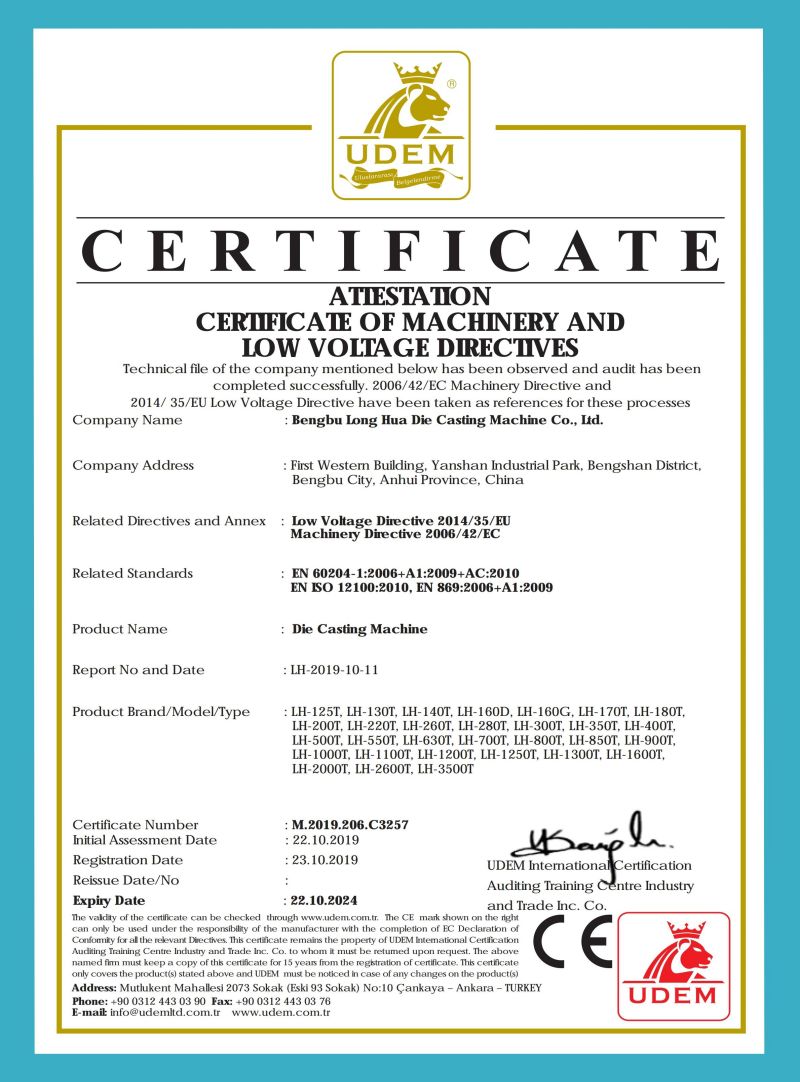

ACERCA DE NOSOTROS

Bengbu Longhua Die Casting Machine Co., Lid es una empresa con sede en la ciudad de Bengbu, provincia de Anhui,

China, que se especializa en la fabricación de máquinas de fundición a presión y equipos relacionados.

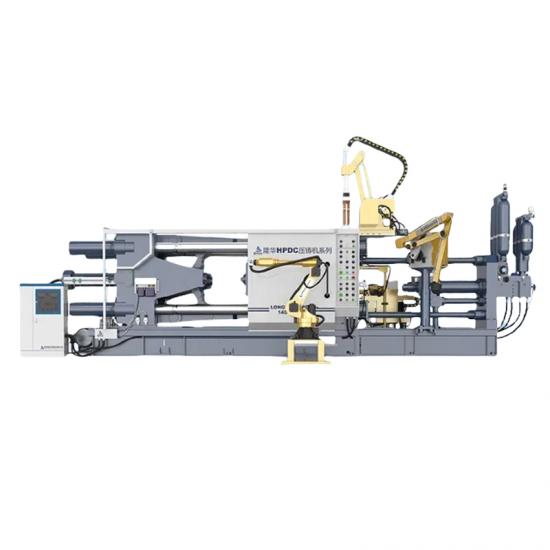

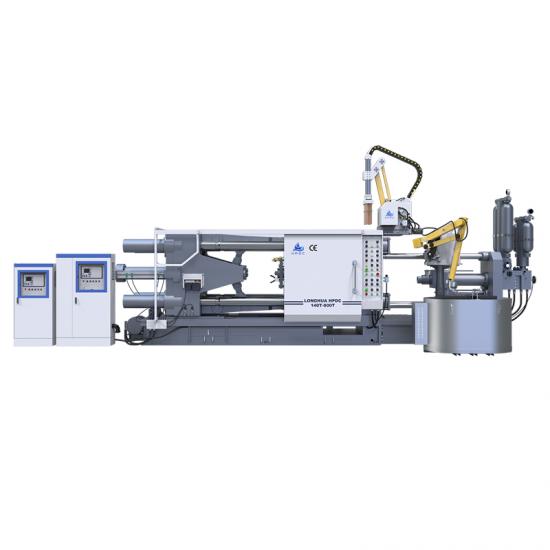

Fundada en 1982, Longhua Die Casting Machine Co., Ltd ha estado involucrada en la industria de la fundición a presión

durante varias décadas. La empresa se centra en la investigación, el desarrollo, la producción y

la venta de varios tipos de máquinas de fundición a presión. La gama de productos de la empresa cubre el frío.

máquinas de fundición a presión de cámara , manipuladores de fundición a presión, robots industriales y equipos periféricos de

máquinas de fundición a presión para satisfacer las necesidades de diferentes clientes.